The Importance of Inventory Management During a Warehouse Relocation

A warehouse relocation can top the list of complex commercial moves. Warehouses are synonymous with a massive inventory of products and stored items. As a result, a proper move will involve a vast amount of manpower as well as a serious need to focus on how and when inventory is packed and then relocated. The trick is to move an empire of inventory without disrupting your daily business and your ability to process incoming orders.

This is why effective inventory management is crucial. The obvious want is to ensure a smooth, cost-efficient transition from start to finish. Here is the importance of inventory management during a warehouse relocation.

1. Keeping Downtime to a Minimum

If your inventory is not properly managed during your warehouse move you might experience operational delays that might have a negative effect on your business. The recommendation is to maintain a strong focus on your inventory management during a warehouse relocation. What are some effective techniques?

One option is to include real-time tracking of all items in transit. You might also choose to put a priority on high-turnover items that should be moved first, preferably over the weekend or when business hours are below peak. Another thought is to make sure that there is a proper sequence to transferring items during a warehouse move to avoid potential “bottleneck” issues.

2. Consider Stocking Strategies

As you empty out one warehouse in order to move to another, a question may arise. Is your current warehouse as organized as it could be when it comes to inventory management? If you feel as though there could be improvements, then you should reconsider how to unpack and stock your inventory in your new space. This will prove especially beneficial if your new warehouse has either a larger or smaller capacity for storage. A warehouse move presents you with a great opportunity to optimize product demand with space utilization.

3. Be Mindful of Potentially Lost or Misplaced Items

Loss is relatable. It happens all the time when your laundry belches out that one sock that somehow suggests the other disappeared somewhere between the tiny walk from your washer to the dryer. If a sock can be that easily misplaced, so can your inventory.

If your warehouse relocation is not properly managed you can and should expect misplaced or damaged goods. That’s why you should always make sure that each and every item is accounted for before, during and even after the move. These days you can even apply QR codes, RFID devices or scanning systems to help ensure that everything is where it should be as your warehouse move progresses. By making solid use of today’s tech, you will be more able to mitigate any potential losses as your items are boxed and then relocated from one warehouse to the next.

4. Project Ahead and Consider Continuity Issues

No one knows your business better than you do. That’s why you should be able to forecast potential orders and know how to properly transition your products accordingly. As you well know, fulfilling those orders without interruption is critical for your operation and your brand.

So, be mindful of what the week prior to and after your move might look like and how that might affect your move. As mentioned, you can expedite your high-traffic products to a new location first or you might even consider holding back a certain level of inventory so that your business is more able to process those forecasted orders without disruption. When you combine forecasted sales with your moving timeline, you will be more able to simplify the logistics surrounding your warehouse move.

5. Check and Double Check

A post-move inventory check prior to stocking will help you to properly identify your inventory and confirm that it has all arrived safely and is accounted for. This will also help you to determine if there are any breakages or discrepancies that need to be resolved before you make your inventory available for sale again.

Proper inventory management then becomes a big factor when it comes to restocking. If not properly managed, then you may have to deal with additional expenses associated with emergency reorders of misplaced or damaged stock, excess labor hours committed to reconciling errors and wasted space due to inefficient planning when it comes to loading and unloading your inventory. These are just a few examples of how poor inventory management during a warehouse move could end up costing you more than anticipated.

This is why warehouse inventory management is essential when it comes to your big moving day. Yes, logistically speaking a warehouse move can present a mountain of issues but as the saying goes, “There is only one way to eat an elephant: one bite at a time.” With apologies to elephants and elephant lovers, the axiom is applicable to almost every part of your life and, especially so, when it comes to managing a big warehouse relocation.

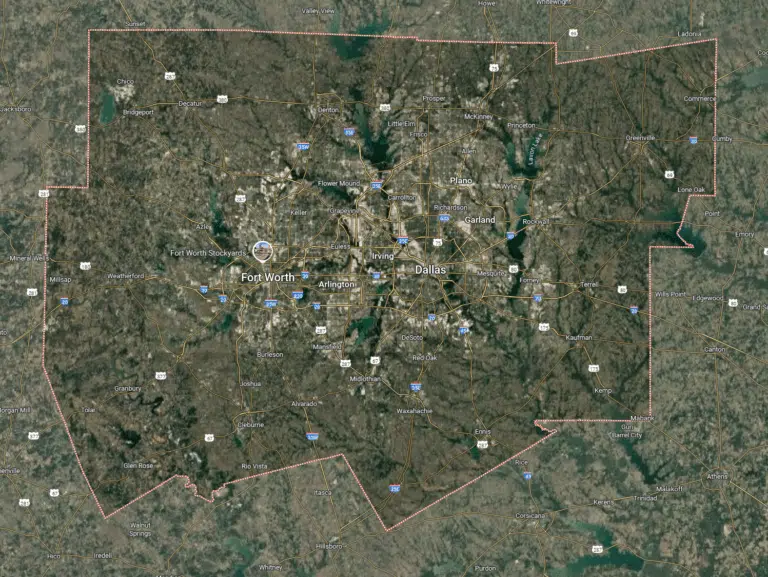

If you are looking for more information or resources on how to ensure a smooth transition during a warehouse move then please reach out and speak to one of our moving and relocation specialists here at IMS Relocation. IMS has been serving the Dallas-Fort Worth metro area since 1991. We are a fully vetted and insured team of moving experts that have seen and done it all – including warehouse moves and other commercial moves including rigging and crating. We encourage you to drop us a line or give us a call today and ask about a free quote for your warehouse move.